Die castings are widely used in various fields. The test content of each product is also different.

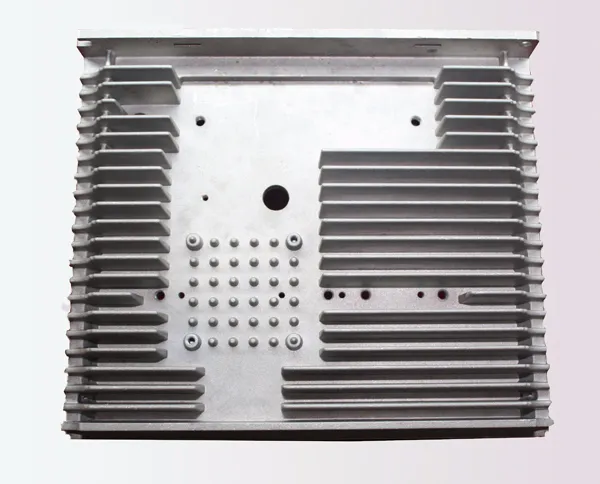

1. Casting size: The shape and size of the die-casting should meet the requirements of the casting mold.

2. Surface quality: The blank shall not have casting defects such as countersunk holes, scabs, cracks, cold partitions, broken cores, etc. that affect the dimension detection of die castings.

The surface must be smooth, flat, and clean. Remove burrs from stock casting heads, air outlets, flesh, seam flash, and rags. Cleans sticky sand and scale.

3. Test requirements: The connector shell of die-casting parts is widely used, such as aviation, automobile, aerospace, navigation, etc. The testing of the connector housing is mainly to confirm its safety and performance. Since most are placed outdoors, a smoke test is required.

1. Strengthen inspection before die-casting, reduce surface watermarks, pores, pinholes, and other parts with serious detection to ensure the compactness of die-casting parts.

2. The mold should be cleaned and maintained after each order.

3. If the die casting has cracks, it can be swept once with soft nylon to reduce peeling.

4. The choice of sand type is very important. If the material is not an overture, brown corundum can be used to reduce spalling.

5. The final solution is closely related to die-casting mold and die-casting technology.

Our die-casting manufacturers should continue to learn and accumulate various die-casting technologies in daily life, constantly find problems and seek solutions in the casting process, so that our foundry business will flourish.

1. For the product itself, the surface of the die-casting part is not dense enough and the texture is loose during the die-casting process. However, this product needs to be passivated with concentrated sulfuric acid during the electroplating process.

It means that the root of the die casting corroded by sulfuric acid, the copper bottom, and the nickel bottom covered on the surface of the product, the electrodeposited layer is thin, and there is no black spot in a short time, but after some time, a black spot appears.

2. Storage status: Some electroplating products have blister packaging and tape and are placed in warehouses with no constant temperature and no greenhouse to control ventilation or humidity. This is part of the reason for mold in die castings.