With the development of science and technology, people's requirements for the safety and beautiful appearance of die casting products are constantly improving. The evaluation of the quality of the parts is different with different uses. This paper analyzes how the die design affects the quality of aluminium dies casting. How produce high-quality parts is of great significance to save materials, energy, shorten manufacturing hours and improve economic benefits.

Many factors affect the quality of die casting part, such as the type and quality of the die-casting machine, the geometric structure of die-casting parts, the rationality of technical requirements, the structure of die, the technical level of operators, etc.

The designer should first fully understand the user's requirements and working conditions, as well as the stress of the die casting. Then the designer chooses the appropriate material according to the use requirements and working environment and understands the die casting performance of the material. In the design, special attention should be paid to making the die casting structure as simple as possible on the premise of meeting the use requirements. The wall thickness shall be proper and uniform, and the necessary die inclination shall be reserved, otherwise, the defects such as pit, air hole, shrinkage porosity, under casting, pull mark, crack, deformation and so on will appear on the die casting. The requirements for dimensional accuracy of die-casting parts should be reasonable, otherwise, it will cause unnecessary troubles to die design, die processing, formulation and management of process conditions, and also cause a large number of unqualified products.

Die casting is made by die casting. There is no doubt that the design, processing and selection of die materials are closely related to product quality. If the die structure is unreasonable, no matter what measures are taken from the process, it is difficult to make the product qualified. Also, the quality of the product and the shelf life of the die will be affected by the die material, the processing accuracy, the surface roughness, the processing trace, the micro-crack of the heat treatment, the thickness of the nitriding layer and the improper assembly of the die.

The average shrinkage of casting material is usually selected when it is given in the form of an average percentage or percentage with a certain range of change. For high-precision die-casting parts, we should pay special attention to the material shrinkage when we design the mould. If necessary, we can make a test mould first, and then design and manufacture the mould for mass production after obtaining the required data on the test mould.

The formulation and implementation of the die casting process are related to the quality of die-casting equipment and the technical level of operators. Under the condition of the existing die-casting equipment in China, it is difficult to achieve stable, reliable and accurate control of the die-casting process parameters. The realization of basic control of the die casting process is the process of combining and using die casting equipment, die casting materials and dies. If the process and main parameters are not strictly carried out, the die casting will have shrinkage, deformation, under casting and unqualified dimensions.

Die is the main tool for die casting. Therefore, when designing the die, we should try our best to make the overall structure of the die and the structure of die parts reasonable, easy to manufacture, easy to use, safe and reliable. To keep the die from deforming in the die casting, the molten metal can flow stably in the die, the casting can be cooled evenly, and the die casting can be fully automatic without failure. Besides, according to the production batch, material conditions and other reasonable selection of suitable mould materials.

From the point of view of strength, it is better to design the die parts as a whole. This kind of mould can be firm and durable, not easy to be damaged and deformed in use. However, if the shape of the die-casting is complex and the parts of the die-casting are complex, it will be difficult to process the die-casting and the accuracy of the processing is not high. If the mould parts are made into a combined type, the processing is greatly simplified, and it is easy to obtain high processing accuracy, and then high-quality die-casting parts can be obtained.

To determine the number of cavities, we should consider the equipment capacity, the difficulty of mould processing, the production batch size, the precision requirements of castings, etc. Especially the multi-cavity mould. Because of the difficulty of die machining, the large error of dimension accuracy, and the difficulty of balancing the runner configuration, the performance of each cavity casting may be inconsistent. The first mock exam is required for high precision, so when the geometry is complex, it is best to use one cavity for one mould. Small castings depend on the situation.

The gating system is not only the channel for liquid metal to fill the die casting mould but also plays an important role in regulating the flow velocity and pressure transfer of the melt as well as the exhaust conditions and the thermal stability of the die design for die casting. Therefore, it is necessary to analyze the structural characteristics, technical requirements, alloy types and characteristics of the casting to design the gating system. It is necessary to consider the type and characteristics of the die casting machine to design a reasonable gating system.

The mould shall be equipped with an overflow groove and exhaust channel with sufficient overflow range, which is very important to ensure product quality. People often ignore the phenomenon that the overflow channel is blocked up prematurely by the incoming liquid metal. A reasonable structure shall be adopted to make the liquid metal flow into the deeper part of the overflow tank first, to ensure that the vent hole is always open for the longest time. Besides, the overflow tank shall be equipped with an ejector rod to remove the metal in the overflow tank.

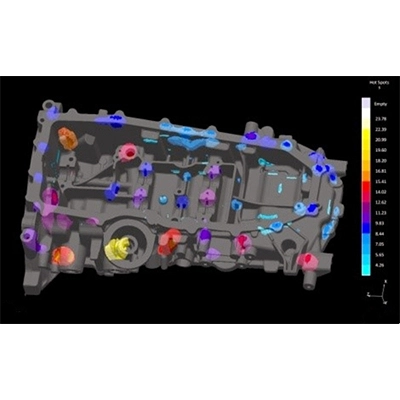

The temperature of the die casting die is an important factor that affects the quality of the casting. Improper mould temperature not only affects the internal and external quality of the die casting (such as porosity, shrinkage cavity, porosity, mucous membrane, coarse grain and other defects), but also affects the dimensional accuracy of the casting, even the deformation of the casting, causes the crack of the die casting, forms the net burrs on the surface of the casting that are difficult to remove, and affects the appearance quality of the die casting. Take the aluminium alloy as an example, the alloy temperature is 670-710 ° C cast into the mould. In the long-term production practice, it is concluded that the best temperature of the mould should be controlled at 40% of the casting temperature. The temperature of aluminium alloy die casting die is 230-280 ° C, which is favourable for obtaining high quality and high yield castings. Generally, the mould does not need gas or electric heating but uses preheating and cooling devices. These devices use oil as the medium according to the requirements to preheat and cool the mould.

When calculating the size of the die casting part, the shrinkage of die-casting materials should be in line with the actual situation, otherwise, die casting components produced will be unqualified. If necessary, the size of the die casting shall be calculated after the actual measurement of the test die. For high-precision products, we even need to take into account the thermal expansion of die-casting parts and the influence of preservation and use environment on the dimensional accuracy of products after die-casting.

The position of the parting surface will affect the mould processing, exhaust, product demoulding, etc.

Generally, the parting surface will leave a trace line on the product, which will affect the surface quality and dimensional accuracy of the product.

Therefore, in the design of the parting surface position, in addition to considering product demoulding, mould processing, exhaust and other issues, we can place the parting surface position where the product surface quality requirements are not high or the dimensional accuracy is not high.

8. Mould deformation effect