In the automotive industry, the transmission housing is a critical component whose quality and performance are critical to the operation and reliability of the entire vehicle. To ensure high-quality manufacturing of gearbox housings, die-casting mold design and optimization of the die-casting process are crucial.

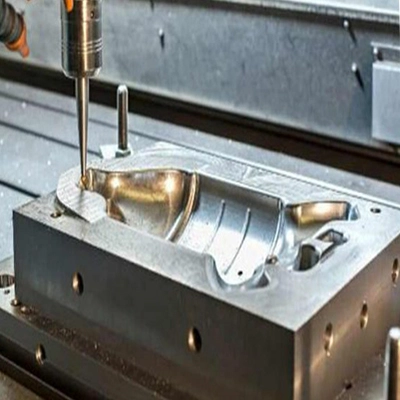

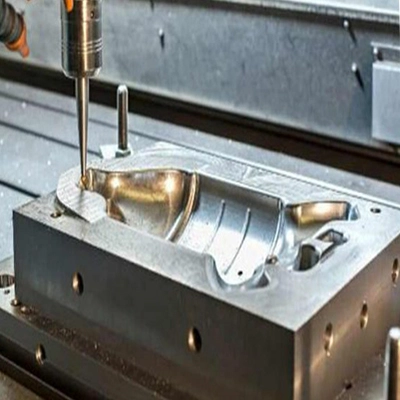

First, the design of the die-casting mold for the gearbox housing needs to take into account complex geometric shapes and structural requirements. The mold should have sufficient strength and stiffness to withstand the high pressure of the casting process. At the same time, the flow channel design of the mold should be reasonable to ensure uniform filling and smooth flow of aluminum liquid and avoid the accumulation of gas and slag.

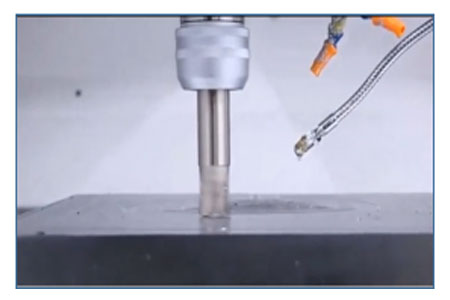

Secondly, the optimization of the die-casting process is crucial to obtaining a high-quality gearbox housing. First of all, it is necessary to control the appropriate pouring temperature and mold temperature to ensure the fluidity of the aluminum liquid and the control of the solidification process. Secondly, reasonable injection speed and pressure can ensure that the aluminum liquid is filled into every corner of the mold to avoid pores and cold seals. In addition, appropriate cooling time and cooling system design can ensure that the solidification and shrinkage process of the casting is controlled, reducing deformation and defects.

To further improve the quality and performance of the gearbox housing, some advanced process technologies can also be used. For example, the use of vacuum die-casting technology can effectively reduce the generation of pores and dross, and improve the density and mechanical properties of castings. In addition, the use of processes such as surface coating or heat treatment can increase the wear resistance and corrosion resistance of the shell.

In summary, by optimizing the die-casting mold design and die-casting process of the gearbox housing, it is possible to ensure the production of high-quality, high-performance parts. This can not only improve the reliability and performance of automobiles but also reduce scrap rates and production costs, contributing to the development of the automobile industry.