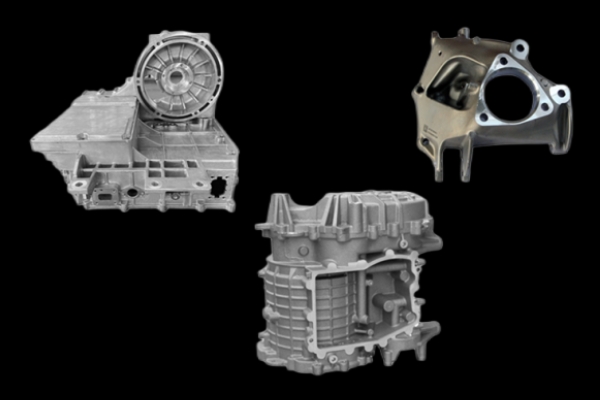

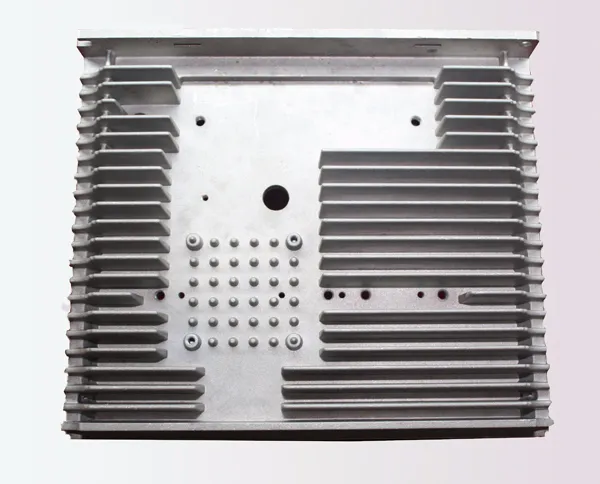

With the continued promotion of automotive lightweight, automotive die-casting parts are changing from functional parts to structural parts, but large die-casting T6/T7 heat treatment exists after the surface is easy to blister, deformation, riveting easy to crack and other problems. Therefore, the market demand for heat treatment-free aluminum alloy materials is increasingly strong, and China is a wave of heat treatment-free material development.

A high strength and toughness aluminum alloy for die-casting without heat treatment and preparation process was developed in China, which was authorized as an invention patent by the State Intellectual Property Office of China on March 31, 2023. It is reported that the product of the invention patent is named "JY-1 high strength and toughness heat treatment-free casting aluminum alloy", whose performance is better than the traditional AISi die-casting alloy, and can realize complex die-casting design, and the alloy can be free from heat treatment after molding, with high strength and toughness characteristics, to meet the parts riveting without cracking, and can adapt to complex die-casting molding process. The alloy has high strength and toughness characteristics, and can be adapted to complex die casting molding process.

This new heat treatment free aluminum alloy material, after high pressure die casting, has stable casting product performance and significantly improved yield strength. After multiple batches of stability verification, its tensile strength >280MPa, yield strength >150MPa and elongation >12% can meet the specific market demand.