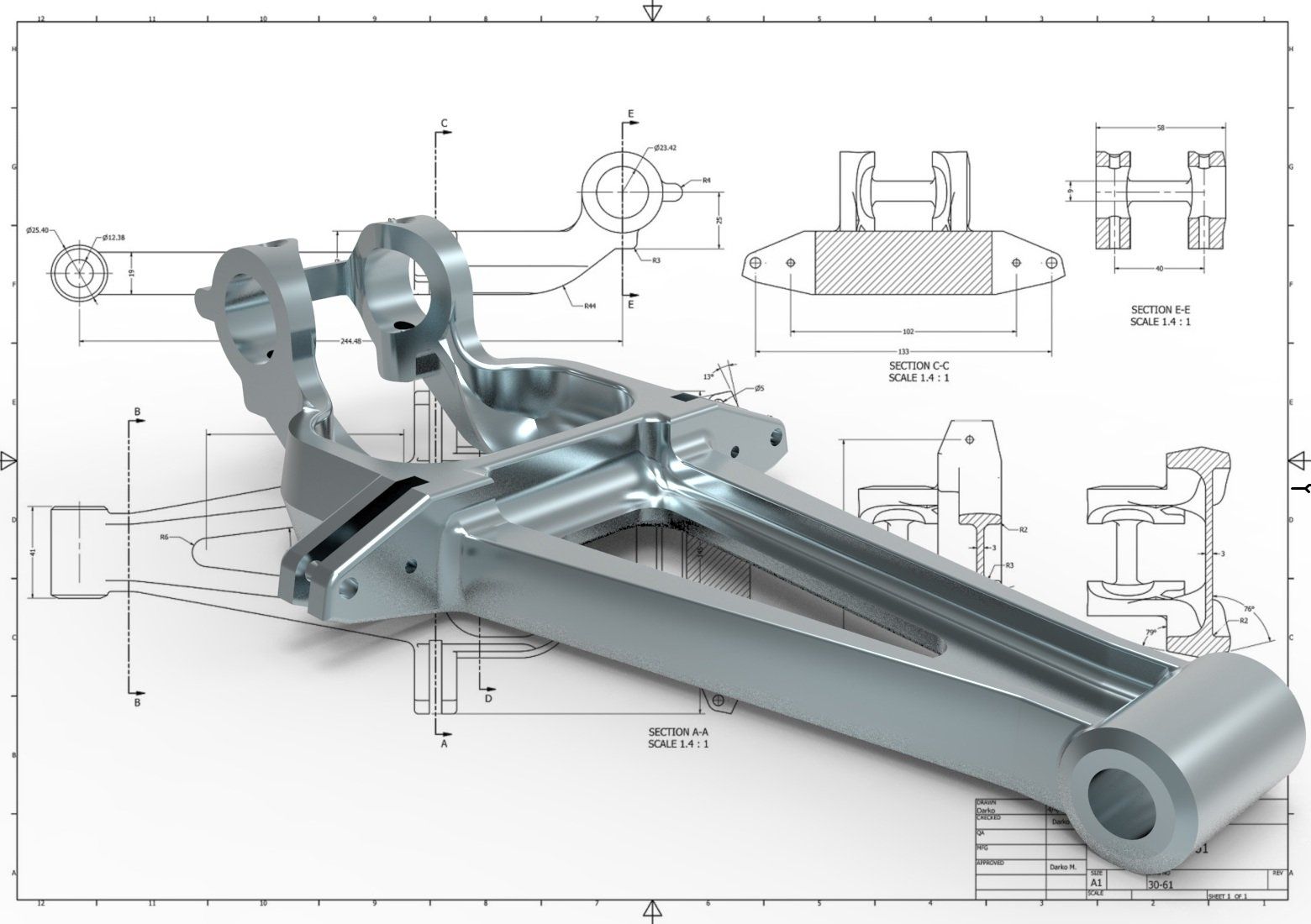

Part design of die-casting parts is an important part of die-casting production technology. The rationality and craftsmanship of the design will affect the smooth progress of next work. For example, aspects such as parting surface design, internal gate opening, alloy solidification shrinkage law, and casting accuracy guarantee are all based on the quality of the structural process of the die casting itself.

一. Things to note when designing die-cast parts

The design of die castings involves four aspects:

a. That is, the requirements of pressure casting on the shape and structure of parts;

b. Process performance of die castings;

c. Dimensional accuracy and surface requirements of die castings;

d. Determination of the parting surface of die castings.

二. Structural design principles of die castings

1. Correctly select the material of die castings;

2. Reasonably determine the dimensional accuracy of die castings;

3. Try to make the wall thickness evenly distributed;

4. Add craft corners to each corner.

一. Design requirements for die castings

1. The shape and structure requirements of die casting parts: a. Eliminate internal undercuts; b. Avoid or reduce core pulling parts; c. Avoid core intersections.

2. Wall thickness requirements for casting design: a. Thicker wall thickness of the part will significantly reduce the mechanical properties of the die casting. Thin-walled castings have good density, which relatively improves the strength and internal pressure resistance of the casting; b. According to the surface area of the die casting, the reasonable wall thickness of aluminum alloy castings is as follows: die casting surface area/mm2 wall thickness S/mm≤251.0~3.0>25~1001.5~4.5>100~4002.5>4003.5~6.0.

3. The intersection of each part of the die-casting part should have rounded corners (except at the parting surface) so that the metal can flow smoothly when filling, gas can be easily discharged, and cracks caused by sharp corners can be avoided.