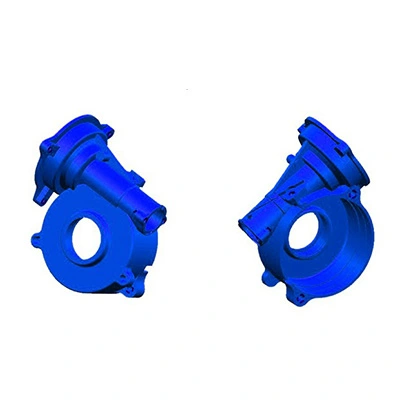

In the manufacturing process of electric vehicles, aluminum die-casting parts have become a popular choice within the industry due to their unique performance and advantages. Aluminum die-casting technology not only provides high-quality parts but also meets the strict requirements of the automotive industry for light-weight and environmental protection.

1. The light-weight nature of aluminum die-casting parts is one of their greatest advantages. The density of aluminum alloy is only about one-third of traditional steel, which significantly reduces the overall weight of electric vehicles, thereby improving energy efficiency and dynamic performance. Additionally, light-weigh helps reduce vehicle energy consumption and emissions, aligning with the contemporary pursuit of sustainable development.

2. Aluminum die-casting parts can be designed integrally, combining multiple small parts into one complex large structural component. This integrated production not only reduces assembly complexity but also lowers production costs and time. At the same time, integrated structural components can also improve the overall rigidity and safety of the vehicle.

3. Aluminum die-casting parts have excellent corrosion resistance and wear resistance, meaning they can maintain long-term performance and stability in harsh environments. These properties ensure the reliability of electric vehicles under various road conditions and climate scenarios.

4. Aluminum material itself has good recyclability, which is an advantage that cannot be overlooked in today's society with increasing environmental awareness. Using aluminum die-casting parts not only reduces resource consumption but also allows for recycling and reuse at the end of the part's life, reducing environmental pollution.

In summary, custom aluminum die-casting parts for electric vehicles, with their advantages of light-weight, integrated production, durability, and environmental friendliness, are gradually becoming an important component of electric vehicle manufacturing. With continuous technological progress and further cost reduction, it is expected that aluminum die-casting parts will play an increasingly important role in the electric vehicle industry in the future.