With the need for a light-weight, energy-saving, and emission reduction, aluminum alloys are more and more used in transportation fields such as aerospace, automobiles, and ships. The use of light-weight materials for automotive parts is an effective way to reduce the weight of a vehicle. Aluminum dies casting is the preferred choice due to its excellent material properties, ease of forming, and light-weight. The application of aluminum alloys die castings in automobiles mainly focuses on housing parts, engine parts, and other components.

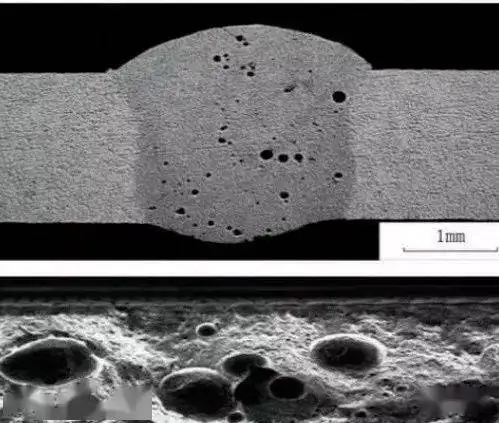

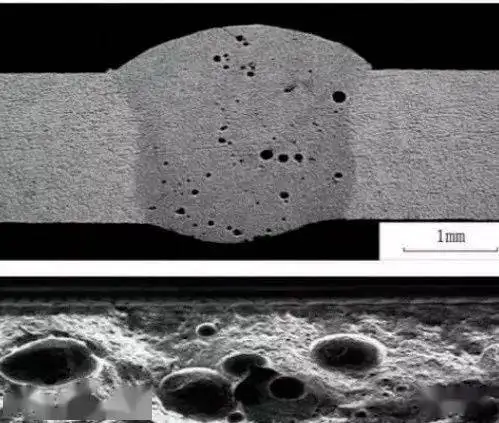

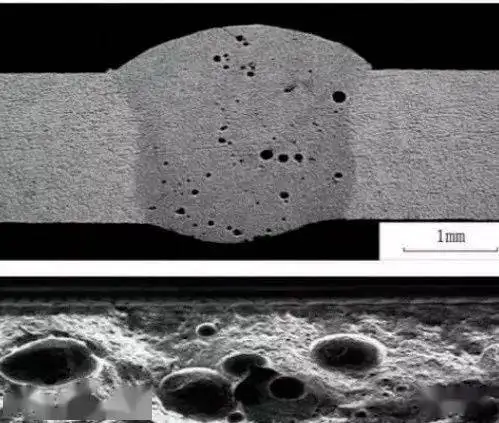

1 The shape of pores in aluminum alloy die castings

Porosity is a spherical porous defect with a smooth inner surface in die castings. Generally, the gas precipitated in the form of bubbles during the cooling and solidification process is too late to discharge the liquid level and remains in the die casting to form. Can not be discharged in the casting solidification process to form a small scattered pore, the so-called pinhole, and more round and uneven, often appear in the thick section of the casting and the cooling rate is slower parts.

2 Techniques for optimizing stomata

2.1 Dual-channel high vacuum technology

Through the application of the new dual-channel high vacuum technology, the gas content in the mold cavity and the pressure chamber is reduced to make it close to the vacuum state, and the application of purification and degassing technology is increased to reduce the gas content of the melt, to reduce the formation of air holes in the die casting.

2.2 Optimization of the powder coating process

Optimize the powder coating process, and reduce the residual amount of mold release agent by shortening the powder coating time, improving the nozzle direction, and prolonging the blowing time, which can effectively avoid the intensive pinhole defects caused by the instantaneous vaporization of molten aluminum and moisture.

2.3 Ways to Improve Porosities for Aluminum Alloy Die Casting

Reasonable choice of high-speed switching point has a great influence on the internal quality of die casting parts. Colleagues improved the pouring system of die casting parts according to the internal quality requirements of products, which has positive significance for the improvement of die casting part’s quality.