Scope of application:

Auto parts, electronic enclosures, communications, motors, aviation, ships, home appliances, furniture accessories, digital enclosure, handicrafts, security product enclosures, LED lighting (lampshades), and some new energy industries, etc.

Some high-performance, high-precision, high-toughness aluminum die castings are also used in large aircraft, ships, and other industries. It is used on the parts or shells of some equipment because the aluminum alloy forming process has become the most widely used process.

Feature:

Durability: Aluminum has strong stability and oxidation resistance, and aluminum alloy castings will not rust and corrode. The surface adopts electrostatic powder spraying and fluorocarbon coating, and the product can remain colorless for a long time.

Plasticity: Aluminum has good malleability and is convenient for various shapes and designs. It has toughness, can be used repeatedly, and has a wide range of applications.

Safety: Die-casting parts have undergone rigorous testing, such as earthquake resistance, wind pressure resistance, and weathering resistance. The unique casting method makes the manufacturing work easy, reduces the burden of handling and construction operations, and reduces the risk.

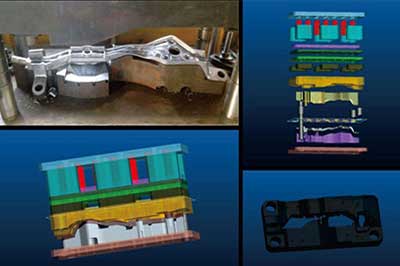

Creativity: Engineers open mold production according to customers' preferences and needs.

Lightweight: Die castings are light in weight, making installation and maintenance more convenient.