Die casting mold is important to process equipment in die casting production. The molten metal is cooled and solidified in a die casting mold to form a die casting. The shape, size, quality, and smoothness of die casting production are all closely related to the die casting mold, so it's crucial to design the correct and reasonable die casting mold.

The following points should be paid attention to in die casting mold design:

(1) Adopt advanced and simple structure as far as possible to ensure a stable and reliable operation and convenient daily maintenance and repair.

(2) Considering the modifiability of the pouring system, necessary modifications can be made in the debugging process.

(3) Reasonable selection of tolerances, scales, and machining allowances to ensure reliable mold fit and required die-casting accuracy.

(4) Select appropriate mold materials and reliable heat treatment technology to ensure the service life of the die casting mold.

(5) It shall have sufficient stiffness and strength and be able to withstand the clamping pressure and swelling force without deformation in the die-casting production process.

(6) Use standardized die-casting mold parts as far as possible to improve the economy and interchangeability.

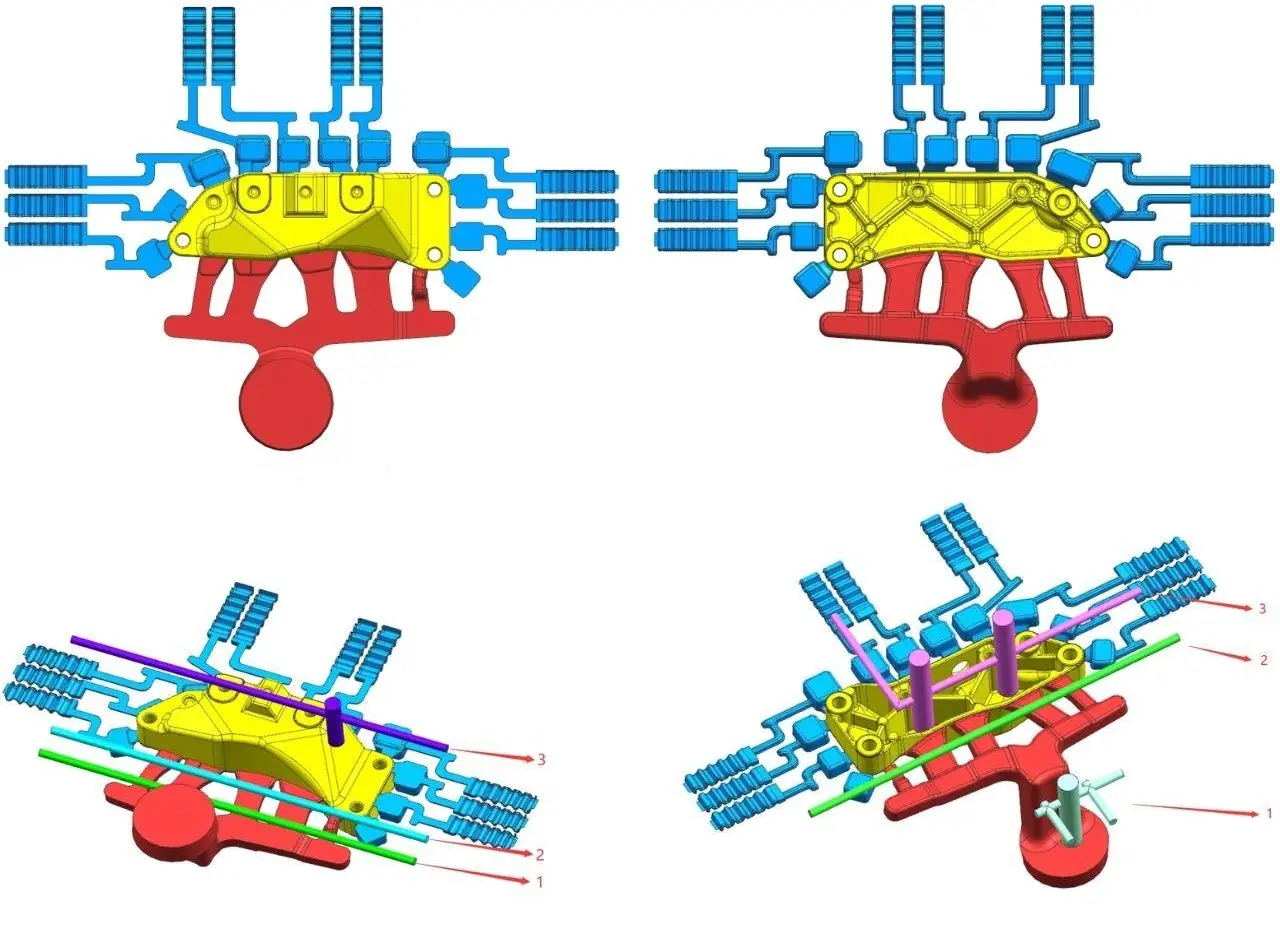

New technologies have been making breakthroughs driven by innovation. EMP Tech Co., Ltd. has a professional mold design team who can design through 3D models and develop new products through mold flow analysis and validation, ensuring that it provides satisfactory products for customers. If you are interested in our die casting mold design, we will discuss the design details according to your drawings and try our best to fulfill your requirements. Welcome to consult us.