1. Overview of Electric Vehicle Market

New energy vehicles are an important direction for the transformation and upgrading of the global automotive industry. As a centralized carrier for the integration and innovation of emerging technologies and the automotive industry, new energy vehicles have become the focus of industry competition in the world's major automotive countries. At present, major developed countries and regions in the world regard new energy vehicles as an important strategic direction for future development and accelerate their industrial layout. In 2019, the global sales of new energy vehicles was approximately 2.21 million, an increase of nearly 10% year-on-year, of which pure electric vehicles still accounted for the main force, accounting for 74% of the overall sales of new energy vehicles, and plug-in hybrid vehicles accounted for 26%.

From the perspective of models, the top ten models with the largest sales of new energy vehicles in the world are Tesla Model 3, BAIC EU series, Nissan Leaf, BYD Yuan/S2 EV, SAIC Baojun E series, BMW 530e/Le, Mitsubishi Outlander PHEV, Renault Zoe, Hyundai Kona EV and BMW i3, among which Tesla Model 3 won the top-selling model with a new sales volume of 300,000 units. In December, 53,000 vehicles were delivered in the month, setting a new record for single-month delivery. Obviously, in the next ten years, electric vehicles will become an increasingly important part of our automotive future. And the demand for aluminum die-casting parts will be increased as well, so what does this mean for aluminum die-casting parts?

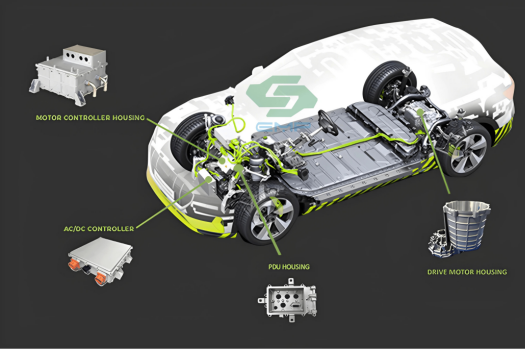

2.The influence of aluminum die casting parts on electric vehicles

Aluminum alloy, which has the characteristics of high strength and strong conductivity, can be used for die-casting electric vehicle parts. It can be cast quickly and reliably, for example by a high pressure die casting process. After casting, a suitable alloy must maintain its properties sufficiently to meet the necessary applications. In recent years, the development of aluminum alloy die-casting technology has generally been through continuous optimization and adjustment of the composition of alloy materials, combined with high vacuum die-casting technology and heat treatment process parameter adjustment, to give full play to the process characteristics of alloy materials, with the help of high-pressure injection and low-speed filling continuously improve the comprehensive mechanical properties of die-casting alloy materials.

3.Electric Vehicle battery housing

The density of aluminum alloy is 2.7g/cm³, and aluminum alloy has obvious advantages in terms of compression or welding. The density of magnesium alloy is 1.8g/cm³ and that of carbon fiber is 1.5g/cm³. These materials are used to produce battery trays, which will greatly improve the lightweight level of new energy vehicles. As known that the battery housing are mainly uses AlSi10MgFe, ENAC43400, A380 materials for aluminum alloy die-casting. The battery housings die cast from these materials have good plasticity and excellent corrosion resistance, especially no stress corrosion cracking tendency, and good welding performance, making these aluminum materials extremely suitable for the application of this project. In order to ensure the product quality of aluminum alloy die castings, it is necessary to adopt advanced welding technologies such as friction stir welding to ensure that the products are integrated.

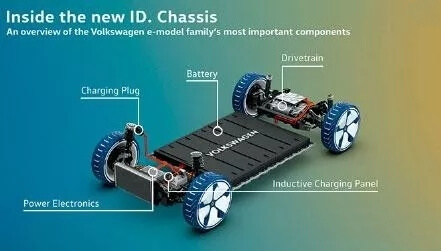

Especially built BEVs use "skateboard"-style platforms, such as Rivian and Volkswagen MEB platforms. Usually, the battery housing is located between the axles, and the motor and control system are installed above the axles.

Which shows a typical method that uses a grid-type (or egg-shaped carton) structure to fix and protect the battery module within the frame and the lower cover (providing both protection and chassis integrity).

4.Summary

Nowadays, the development of electric vehicles is getting better and better, the annual sales are gradually increasing, the popularity of the public is also getting higher and higher, and it brings more and more opportunities to the aluminum alloy die-casting industry.It is believed that the demand for aluminum alloy die castings for electric vehicles will increase in the near future.

New energy vehicle chassis

New energy vehicle battery