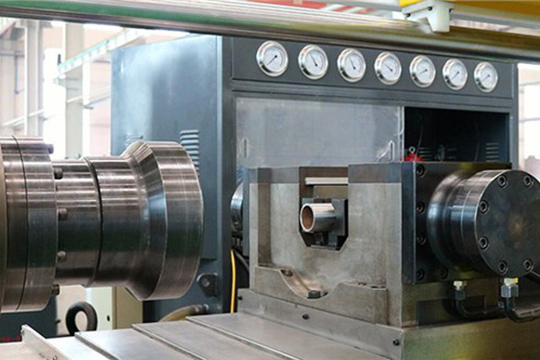

High-pressure aluminum casting is a kind of widely used parts and components. Because aluminum has stable performance and is durable and hard, which is frequently used in auto parts and some larger structures of industrial machinery and equipment, but sometimes the surface of the high-pressure aluminum casting is oxidized. In this case, oxidized casting is very unstable at work which may lead to breaking down.

After observation and research, it finds that there are many factors causing surface oxidation of high-pressure aluminum casting. The equipment of high-pressure aluminum casting is not cleaned properly after use, which leads to many material impurities sticking to the surface of the castings and oxidation over time. Or the solution in the casting, which generally contains metal elements, also produces oxidation if kept in the equipment for a long time; In addition, some high-pressure aluminum castings are oxidized due to equipment damage which is caused by improper use during operation.

In the face of the above oxidation reasons, we need to take corrective measures according to the actual situation and timely clean the casting after use so as to keep the surface free from other impurities and pollution; Improve the casting capacity of the object and adopt appropriate production mode; Clean the metal solution in the equipment in time, fill it with clean water after cleaning, repeat several times and thoroughly clean; For the processing of the production material, remove the impurities contained in the material effectively and appropriately reduce the equipment service time.

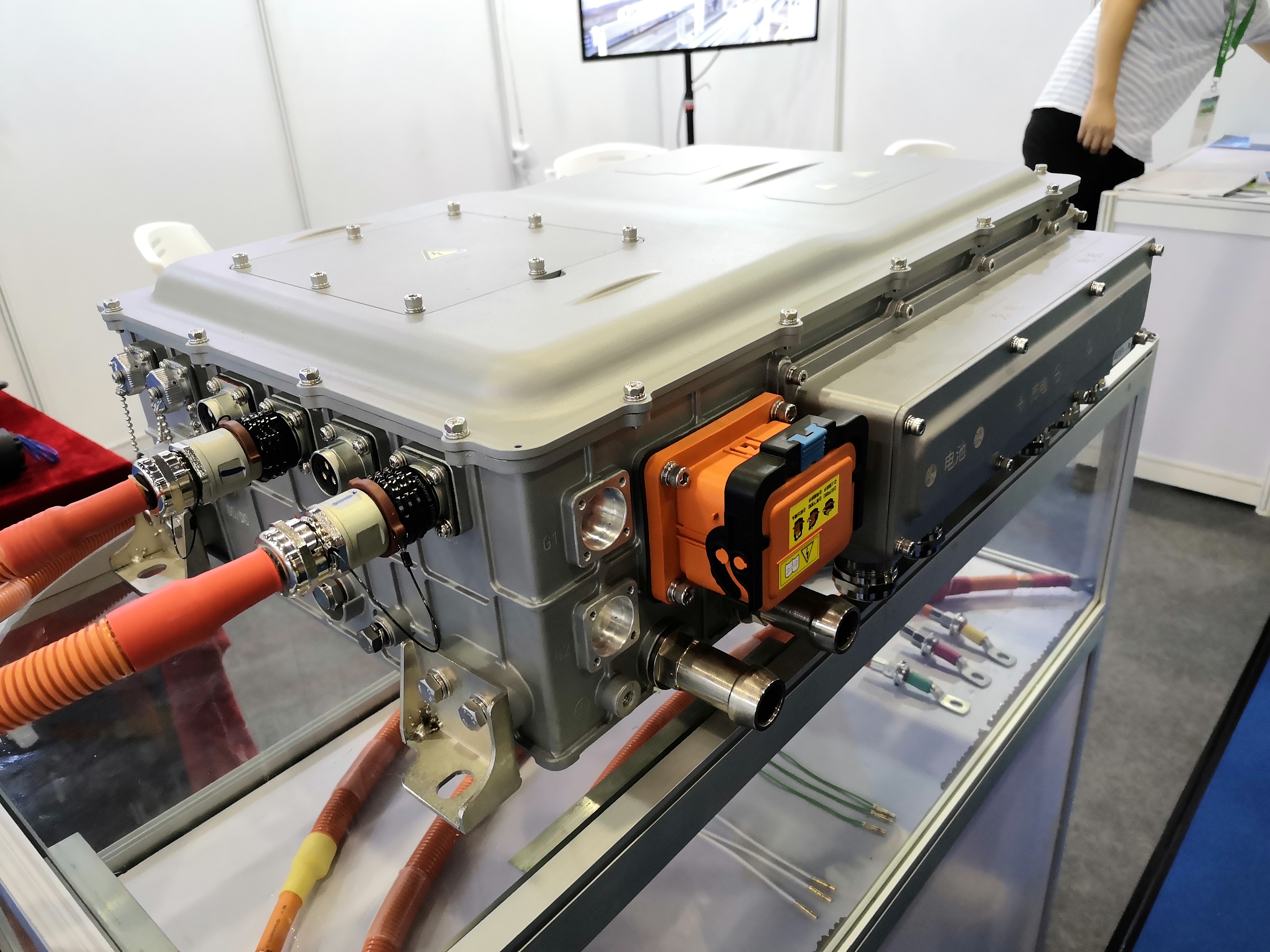

It is a problem widely concerned that the quality of the high-pressure aluminum castings. Some small manufacturers don't strictly control the quality of high-pressure aluminum castings when raising yield at the same time. It is quite easy to cause the failure of mechanical equipment using such defective goods, so you can choose EMP Tech co., LTD. for high-pressure aluminum castings. We have more than 20 years of experience in research and development, manufacturing, and precise processing in the aluminum industry and look forward to cooperating with you.