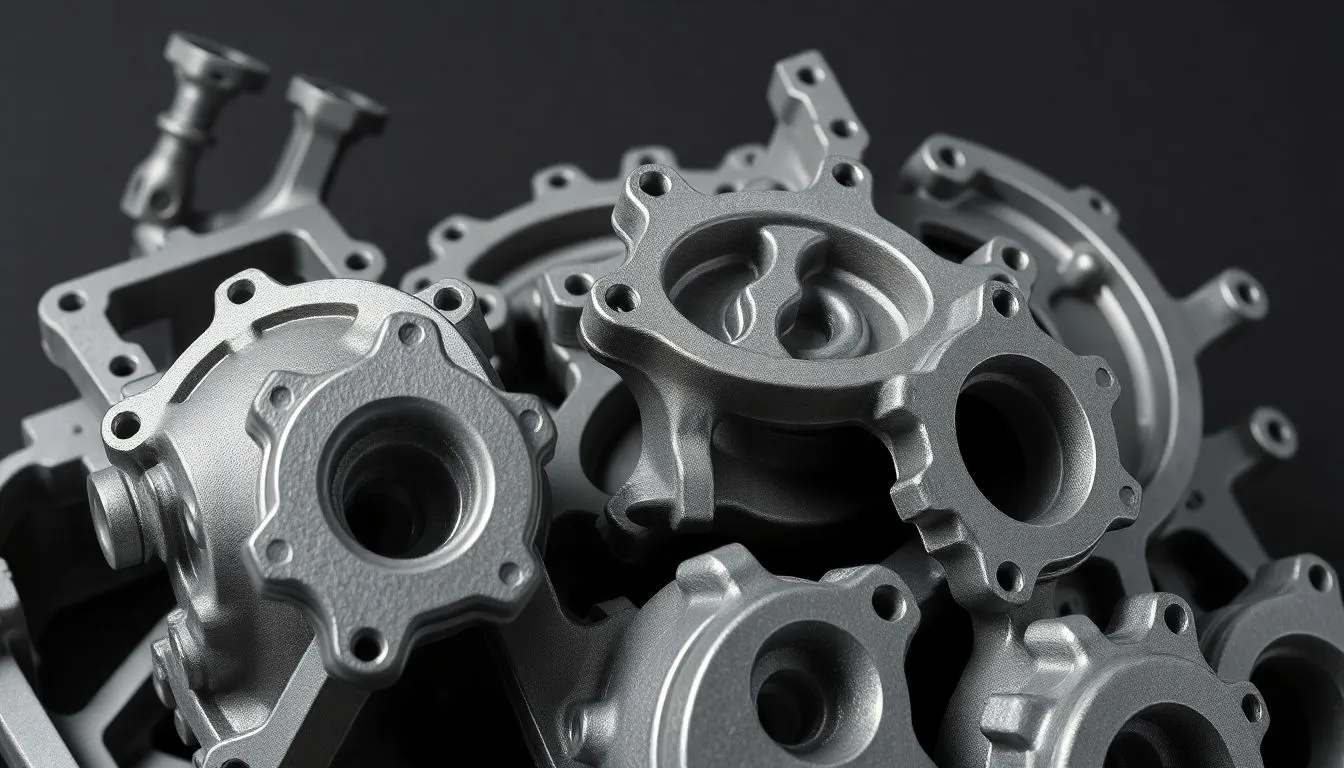

Generally, the last process of the aluminum casting blanks produced in aluminum casting plants is shot blasting, so what are the differences between shot blasting aluminum castings and ordinary aluminum castings? Here is an exclusive explanation for you.

1. The surface of the shot blasting aluminum castings can present the natural color of the matrix.

After shot blasting treatment, the surface attachments, thin edges, wings, spots and scratches can be removed, so that the workpiece presents the original color of the matrix.

2. Eliminate stress concentration on the surface of ordinary aluminum castings.

During the cooling process of aluminum castings, the uneven wall thickness and the inconsistent cooling rate lead to the stress concentration on the surface. After shot blasting cleaning, the surface structure of the shot blasting aluminum castings can be improved, the surface stress (tensile stress) concentration can be eliminated, the fatigue strength can be strengthened, and the surface hardness can be slightly increased.

3. The surface of shot blasting aluminum castings is more aesthetic.

Because the projectile is spherical, the projectile produces small, concave, and spherical holes on the aluminum castings, which makes the surface just like a concave mirror. Under the light, it shines like stars, which is pleasing to the eye.

4. The surface spraying adhesion of shot blasting aluminum castings is significantly improved.

After shot blasting cleaning, the roughness of the shot blasting aluminum castings can reach Ra1.6 ~ 6.3 μm, and the surface area is greatly increased. At the same time, the surface dirt is eliminated. Therefore, when the surface is sprayed or painted with other coatings, its adhesion is greatly enhanced.