There are many types of die casting tooling, such as zinc alloy die casting tooling, aluminum die casting mold, magnesium alloy die casting tooling. Although the objects used are different, the operating principles are the same. The quality of die casting tooling, which is a necessary thing for the production of die casting components greatly affects the quality of the die casting components, and the flow gate is an important "organ" of the die casting tooling.

The flow gate is the channel through which the molten metal enters the cavity, which can control the flow direction, the velocity of the molten metal, and the direction of the inflow in the beginning and has a direct impact on the filling and molding of the die casting components. The flow gate should be selected to ensure the flow path of molten metal is as short as possible, and the flow direction can follow the stirrup and heat sinks of the die casting components as much as possible, and the molten metal can fill from the thick wall to the thin wall; and the flow gate should be easy to cut off without damaging the body of die casting components.

If the die casting tooling is equipped with more than one flow gate, it is necessary to prevent the impact caused by the confluence of the molten metal from generating eddy currents, gas inclusion, oxidation inclusions and other flaws.

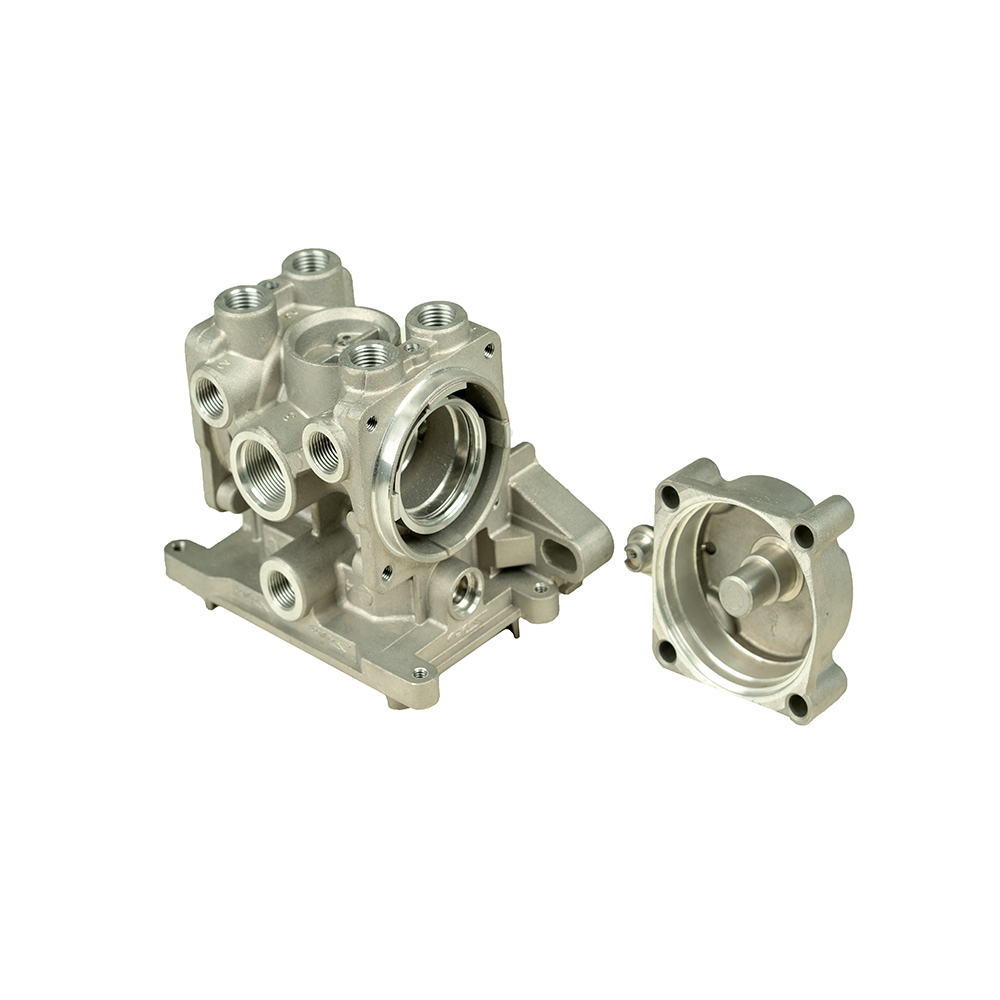

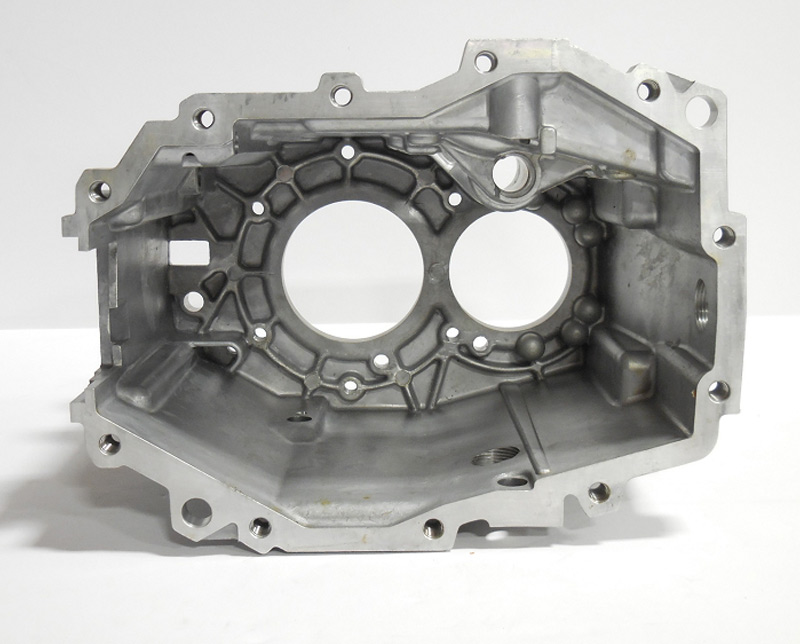

EMP is a global full-service manufacturer of precision aluminum die casting products. We have more than 20 years of experience in R&D, manufacturing and precision processing in the aluminum die casting industry. We are proud to cooperate with some of the world's top automotive, engineering, electronics and telecommunications companies. If necessary, please feel free to consult.