1. Spectrometer

The spectrometer is used to detect the composition of the material, and the spectrometer automatically displays the numbers and analyzes them to determine which elements are contained in the article.

2.CMM

Coordinate Measuring Machine (CMM) refers to an instrument capable of measuring geometric shapes, lengths, and circumferential divisions within the space of a hexahedron. Mainly used for the measurement of boxes, racks, gears housing, blades, curves, curved surfaces, etc.for machinery, automotive, aviation, military industry, and other industries. It can accurately detect the size, shape, and form tolerance of the workpiece, to complete tasks such as part inspection, shape measurement, and process control.

3. Universal Testing Machine

A universal testing machine, also known as universal material testing machine,it can perform mechanical tests on metals and other materials, including tensile strength, bending strength, elongation, yield strength, etc., optional fixtures can test sheets, bars, and other materials Complex structure.

4. Roughness Tester

It has the characteristics of high measurement accuracy, wide measurement range, simple operation, easy to carry, stable work, etc. It can be widely used in the detection of various metal and non-metal processing surfaces.

5. Contour Tester

The contour tester is an instrument for testing and inspecting the contour, two-dimensional size, and two-dimensional displacement of an object. As a precision measuring instrument, it is widely used in automotive manufacturing and railway industries.

6. Leak Test Machine

A leak tester can detects liquid or air leakage in a pipeline or container. An ultra-high sensitivity combustible gas leak detection instrument. Using the semiconductor detection principle is more suitable for finding and detecting the location of micro-leakage of combustible air.

7. X-ray Machine

X-ray testing is the best non-destructive inspection method for detecting internal defects of castings. It can be inspected to verify the internal structure and integrity of the sample.

8. Hardness Tester

A hardness tester is a special instrument used to measure the surface hardness of paint. There are two types of hardness testers, desktop hardness testers, and portable hardness testers. Desktop hardness testers are mainly used in laboratories and have the advantage of high accuracy.

9. Ultrasonic cleaning

Ultrasonic cleaning is the use of ultrasonic cavitation, acceleration, and direct flow in the liquid to, directly and indirectly, affect the liquid and dirt, so that the dirt layer is dispersed, emulsified, and peeled to achieve the purpose of cleaning. In the ultrasonic cleaning machines currently used, cavitation and direct flow are more used.

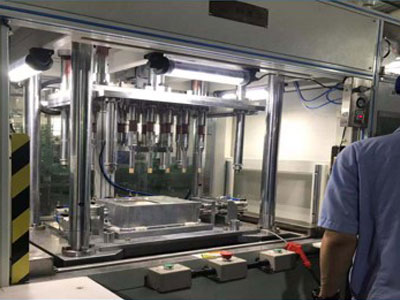

10. Automatic Washing Line

EMP also has an automated cleaning line, which can automatically clean die castings, thereby improving our production efficiency and ensuring product quality, while also saving process costs.