With the rapid development of the electric vehicle industry, the manufacturing process of electronic control housings is also constantly improving. As an efficient production method, die casting plays an important role in the manufacturing of electronic control housings.

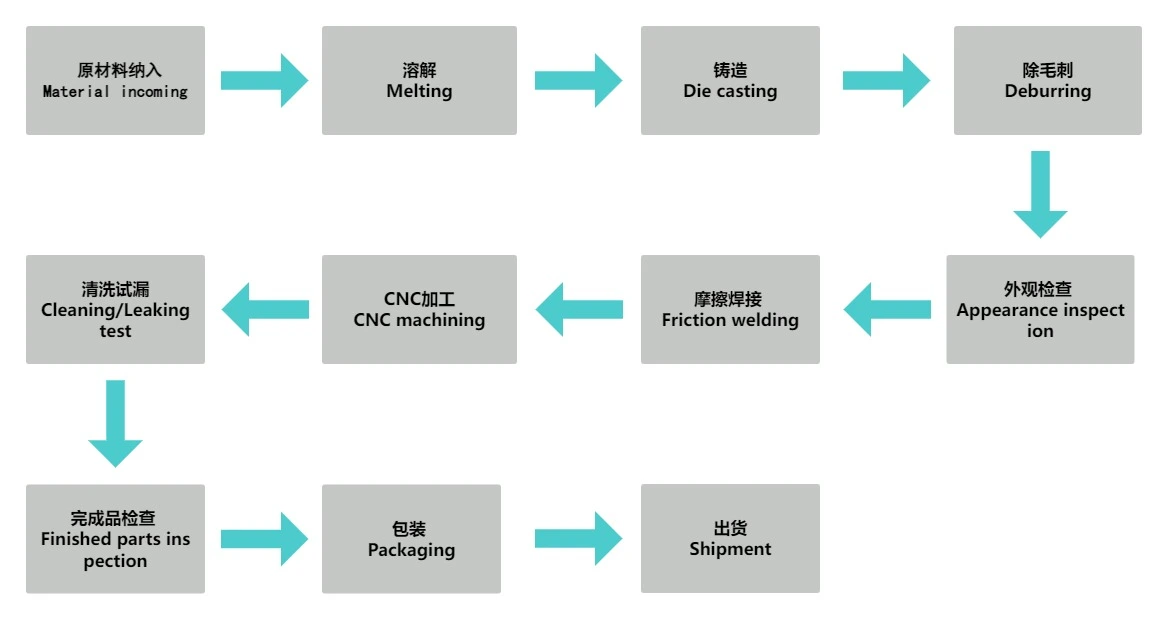

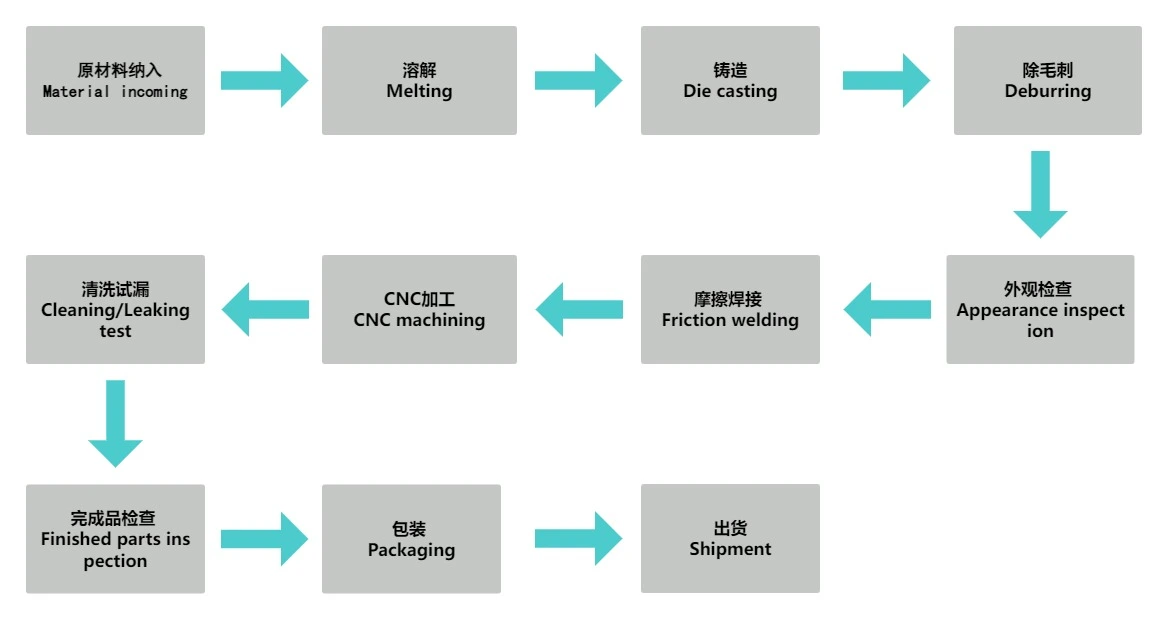

The manufacturing of die-cast electronic control enclosures is a complex project involving precision design and strict process control. First, it is necessary to analyze the die-casting process of electronic control housing parts and determine the main process parameters of die-casting production. This includes parting surface design, pouring overflow system design, ejection system design, cooling system design, and overall mold structure design.

In the die-casting process, temperature control of the mold and molten aluminum is crucial. Uneven or inappropriate mold temperature will lead to casting quality problems, such as shrinkage cavities, pores, and other defects. Therefore, precise control of mold temperature and reasonable flow of aluminum liquid are the keys to ensuring the quality of die castings.

Friction stir welding is a critical step in the manufacture of electronic control enclosures. The oxide layer on the surface of the weld needs to be removed, and a machining allowance of about 1 mm should be left on the upper surface. The weld gap should be less than 0.2mm and the height difference should be less than 0.3mm to ensure welding quality.

Air tightness testing of die castings is a key step to ensure quality and performance. Qualified die castings should have a leakage value not exceeding 0.1kPa under specified test conditions. This standard ensures that every die-cast part meets air-tightness requirements, ensuring product reliability and safety.

The cleanliness of the die-cast electronic control housing is also critical to its performance. In the field of die casting cleaning equipment, waterway cleaning technology and solutions for the "three-power system" shell are particularly important. The cleanliness of the inner cavity particles after cleaning must be kept within 500um to ensure that the waterway is smooth and will not cause fatal damage due to dirt particles.

Quality inspection is the last step in the die-casting process, but it is equally important. Through X-ray inspection, pressure testing, and dimensional measurement, we ensure that each electronic control enclosure meets strict quality standards.

In summary, the manufacturing of die-cast electronic control housings is a complex process involving multiple process steps. From mold design to air tightness testing of castings to final cleanliness requirements, each step requires precise control to ensure product performance and safety. As technology advances and standards improve, these processes will continue to play an important role in the die casting industry.