Die casting is a versatile and efficient manufacturing process that allows for the mass production of metal components with complex shapes and high dimensional accuracy. Among the cutting-edge techniques in this field are high-vacuum die casting and semi-solid and squeeze casting. These methods have been developed to address common issues such as porosity, improve material properties, and expand the range of applications.

High-Vacuum Die Casting

Overview:

High-vacuum die casting is a process designed to eliminate porosity in cast parts. It involves extracting gases from the die cavity before and during the metal injection process. This method ensures that the cavity is under a vacuum, significantly reducing air entrapment and subsequent porosity.

Benefits:

Enhanced Material Integrity: By minimizing gas entrapment, high-vacuum die casting produces components with superior mechanical properties. This makes the parts suitable for critical applications, such as in the automotive and aerospace industries, where structural integrity is paramount.

Improved Surface Finish: The vacuum environment helps to eliminate surface defects, leading to a smoother finish that often requires less post-processing.

Complex Geometries: The technique supports intricate designs and thin-walled sections, expanding the possibilities for complex component manufacturing.

Applications:

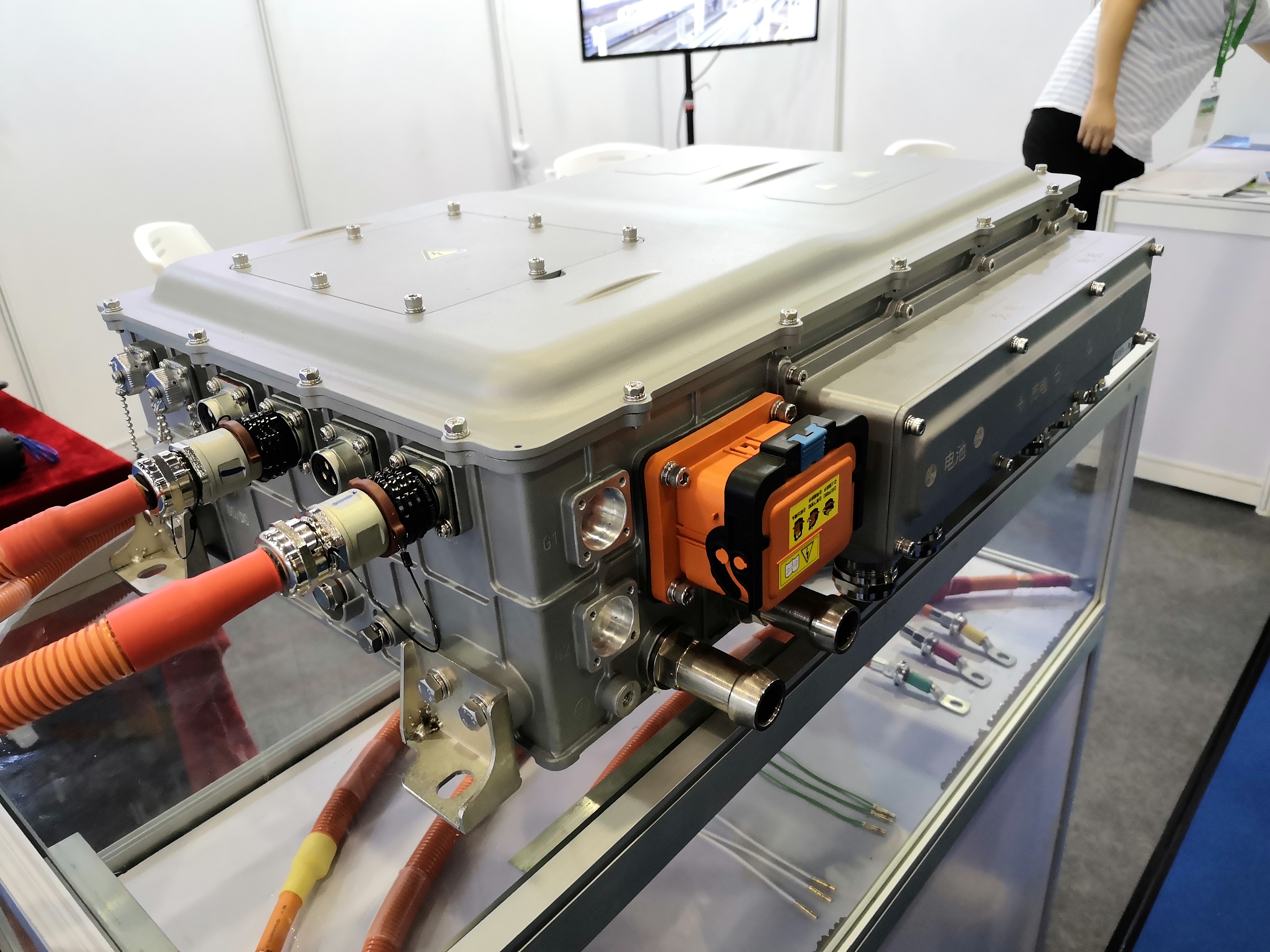

High-vacuum die casting is particularly beneficial for producing lightweight structural components with high strength-to-weight ratios. It is increasingly used in automotive engine parts, gearboxes, and structural components for electric vehicles.

Semi-Solid and Squeeze Casting

Semi-Solid Casting:

This technique involves processing metal alloys in a partially solidified state. The process capitalizes on the thixotropic behavior of semi-solid metals, allowing for better control over the filling process and reducing gas entrapment.

Advantages:

Reduced Porosity: The semi-solid state reduces turbulence during filling, minimizing air entrapment and resultant porosity.

Improved Mechanical Properties: The microstructure of semi-solid cast parts is finer and more uniform, enhancing strength and ductility.

Energy Efficiency: Lower processing temperatures reduce energy consumption and thermal stress on tooling.

Squeeze Casting:

Squeeze casting involves applying pressure during the solidification of the metal. This pressure helps to eliminate porosity and shrinkage defects, resulting in denser and stronger parts.

Advantages:

High Density and Strength: Squeeze casting produces parts with high density and fine microstructures, making them ideal for high-stress applications.

Reduced Defects: The process minimizes common casting defects, such as shrinkage and gas porosity, improving the overall quality of the cast parts.

Versatility: Squeeze casting is suitable for a wide range of alloys, including aluminum, magnesium, and copper-based alloys.

Applications:

Semi-solid and squeeze casting techniques are widely used in the automotive industry for manufacturing suspension components, wheels, and engine parts. They are also employed in the production of electrical components and consumer electronics where high strength and precision are required.

Conclusion

Advanced die casting techniques such as high-vacuum die casting and semi-solid and squeeze casting represent significant advancements in the manufacturing industry. These methods offer improved material properties, reduced defects, and enhanced design flexibility, making them indispensable for modern engineering applications. As industries continue to demand high-performance materials and components, these techniques will play a crucial role in meeting those needs.