Electric vehicle (EV) electronic control systems, often referred to as the "brain" of the vehicle, play a critical role in coordinating various performance aspects. These systems rely on electronic control units (ECUs), which are housed in casings made from integrated circuit components. Given the fragility and cost of these components, they require robust protective housings that offer superior heat dissipation, waterproofing, and dustproofing capabilities. In this article, we will delve into the key aspects of manufacturing EV electronic control casings and battery enclosures, as well as the advanced equipment used in their production.

Importance of EV Electronic Control Casings

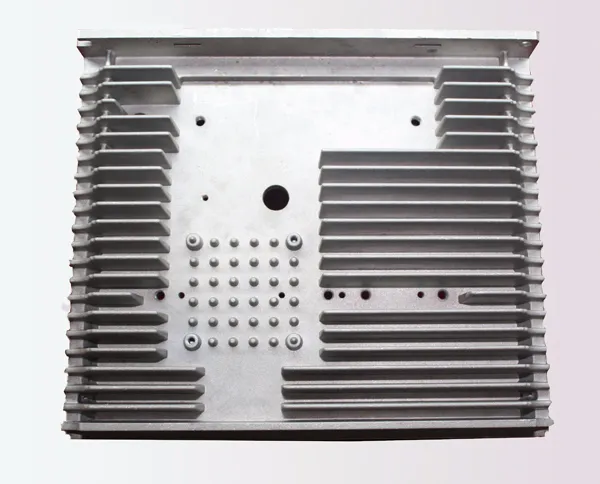

The electronic control casing serves as the protective shell for the components responsible for regulating a vehicle's operations. These casings must ensure that internal components are protected from environmental factors while allowing efficient heat dissipation to maintain optimal performance.

The materials used for EV battery box are typically die-cast aluminum alloys, known for their lightweight and durability. However, these thin-walled components require meticulous machining to prevent deformation and to maintain high standards for waterproofing and dustproofing, often rated at IP67 or higher.

The Complexities of Manufacturing EV Electronic Control Casings

Manufacturing EV electronic control casings is a complex process that involves multiple steps. In addition to machining the front face, the sides and holes of the casing also require precision processing. During this phase, careful attention must be given to the positioning and support of the workpiece to prevent deformation. Achieving high sealing standards is critical, particularly when assembling the casing with the lid, which also must meet the same IP67 waterproofing and dustproofing requirements.

Achieving Quality Standards in Machining

To meet quality standards, the surfaces of the casing must be free from cracks, scratches, and any other defects like pores or bubbles. This necessitates high-efficiency drilling and tapping equipment, which plays a crucial role in ensuring the final product meets all specifications.

The lid of the electronic control casing is also a thin-walled component. It requires precision in terms of flatness and smoothness to ensure a secure and airtight assembly with the casing. Deformation must be avoided during machining, so careful positioning and support are critical to achieving a high degree of sealing when the lid is attached.

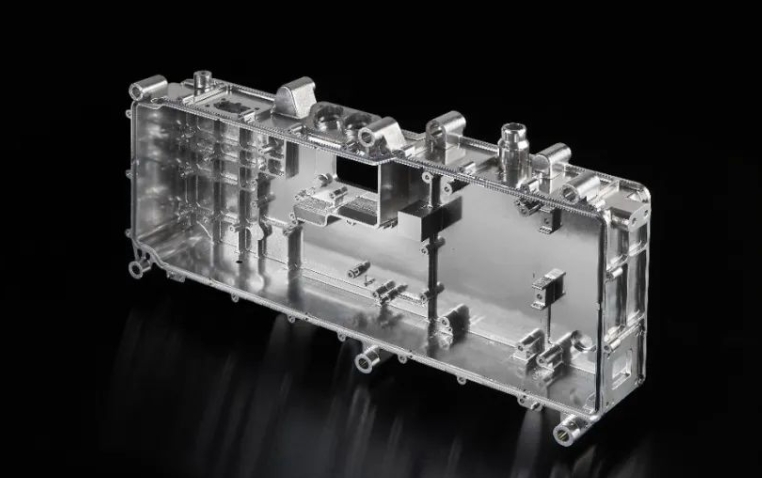

The Role of Die-Cast Aluminum in EV Motor Housings

Die-cast aluminum is not only used in electronic control casings but also in EV motor housings. These housings are designed to reduce the operating temperature and vibration of the motor, contributing to a longer lifespan. The motor casing houses various components, including gears, the main shaft, and the motor itself. The casing is equipped with dual mounting feet to simplify installation using customized reaming tools, locating pins, and jacking screws. Learn about the electric motor casing material.

How Aluminum Motor Housings Are Manufactured

The manufacturing process for aluminum motor housings begins with checking the aluminum alloy for quality, followed by a chemical composition analysis using a spectrometer. The alloy is then melted at approximately 680°C and injected into a die-casting machine. After cooling, the casing is removed with pneumatic tools, and burrs are cleaned off. Subsequent processes such as shot peening, machining, and hand-finishing ensure that the surface is smooth and free of burrs.

The housing is then subjected to induction heating to expand the diameter, allowing for the insertion of windings, which are locked into place once the housing cools. This process ensures that the internal diameter adheres strictly to specifications; any deviation in size can lead to motor failure.

Cleaning and Quality Control in Casing Manufacturing

After machining, the casing undergoes a thorough cleaning process using a combination of reductants, acids, and ultrasonic methods. Each cleaning cycle is followed by a rinsing stage. Once cleaned, the casing is dried in an oven, and a final inspection is performed by the quality control team. Ensuring that the product is free from contaminants or manufacturing defects is critical to its performance and longevity.

The Importance of EV Battery Enclosures

EV battery enclosures are another crucial EV car components in the design and functionality of electric vehicles. These enclosures are tasked with protecting the battery pack, a vital component that powers the vehicle. Typically made from aluminum or steel, battery enclosures need to be lightweight yet strong enough to withstand high temperatures, corrosion, and external impacts.

Composite Materials: A New Frontier in EV Battery Enclosures

One of the key challenges in electric vehicle design is extending the range of the vehicle on a single charge. To address this, the automotive industry is increasingly turning to composite materials for battery enclosures. These materials offer a weight reduction of up to 40% compared to traditional aluminum casings, which significantly improves vehicle performance and range. Additionally, composite battery enclosures help reduce noise and vibration inside the cabin, enhancing the overall driving experience.

Composite materials also offer superior strength and rigidity compared to aluminum or steel, making them an ideal choice for integrating battery enclosures into the vehicle's structure. This not only protects the battery but also adds an extra layer of safety for passengers.

Large-Scale Production Techniques for EV Battery Enclosures

To make EV battery enclosures cost-effective, large-scale manufacturing processes such as pultrusion are employed. Pultrusion enables the continuous production of strong yet lightweight composite parts, which are essential for mass production in the automotive industry. This technique significantly lowers the overall production cost, making electric vehicles more affordable for consumers.

NO.38 Duanzhou 3rd Road, Zhaoqing(526060), Guangdong, China

NO.38 Duanzhou 3rd Road, Zhaoqing(526060), Guangdong, China