Aluminum has become the cornerstone of modern automotive engineering, offering a unique blend of lightweight properties (30–50% lighter than steel), corrosion resistance, and high strength-to-weight ratios. For custom car parts, aluminum alloys like 6061-T6 and A380 are preferred for their adaptability to CNC machining, die casting, and hydraulic forming – processes that enable complex geometries while maintaining ±0.05mm tolerances.

Thermal Management: Ideal for EV battery trays and motor housings, where integrated cooling channels reduce overheating risks.

Design Flexibility: 5-axis CNC and AI-driven simulations allow bespoke designs for racing components (e.g., drift handbrakes) and aerodynamic body kits.

Sustainability: 95% recyclability aligns with global carbon-neutral initiatives, critical for OEMs targeting ESG compliance.

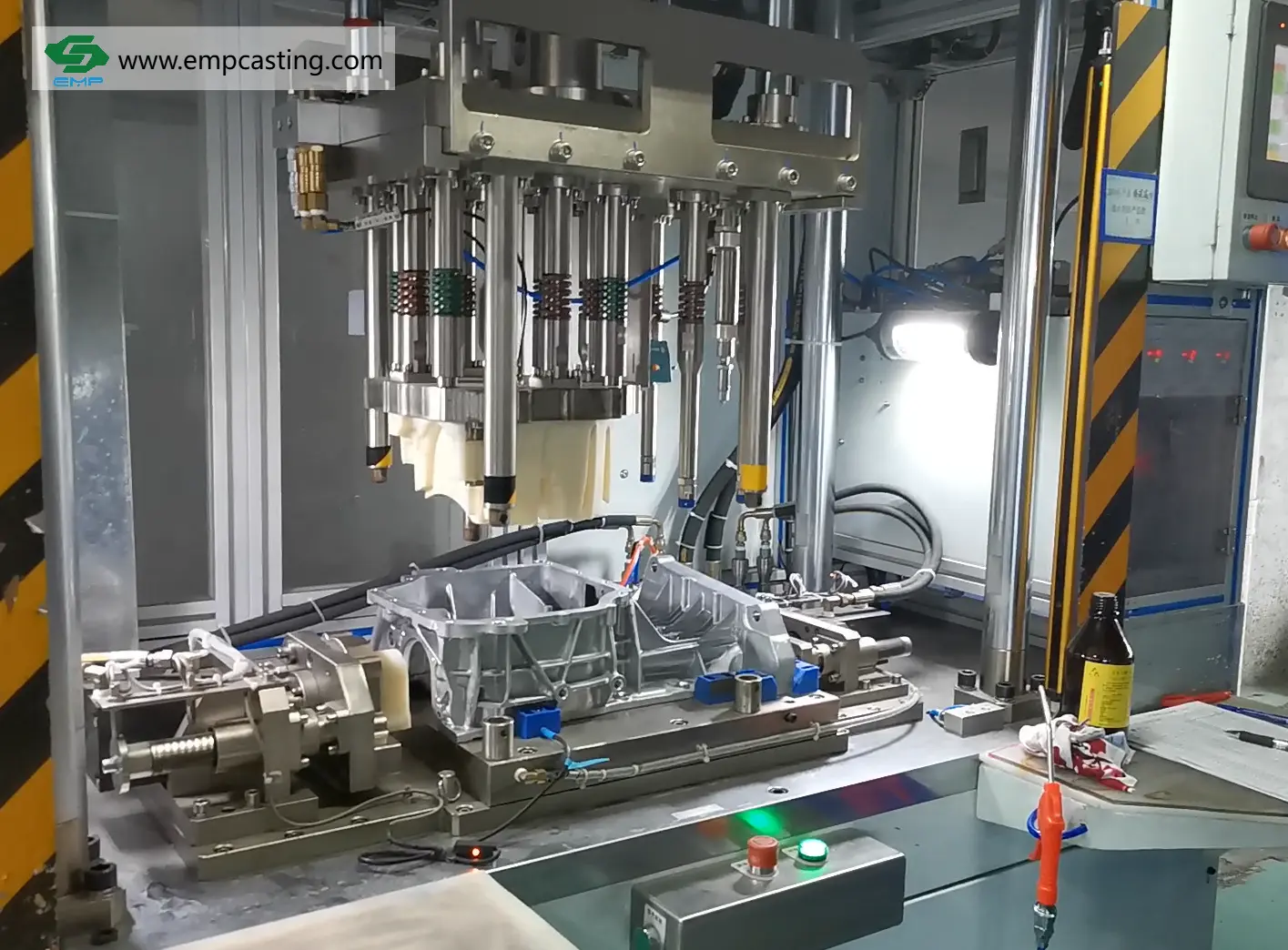

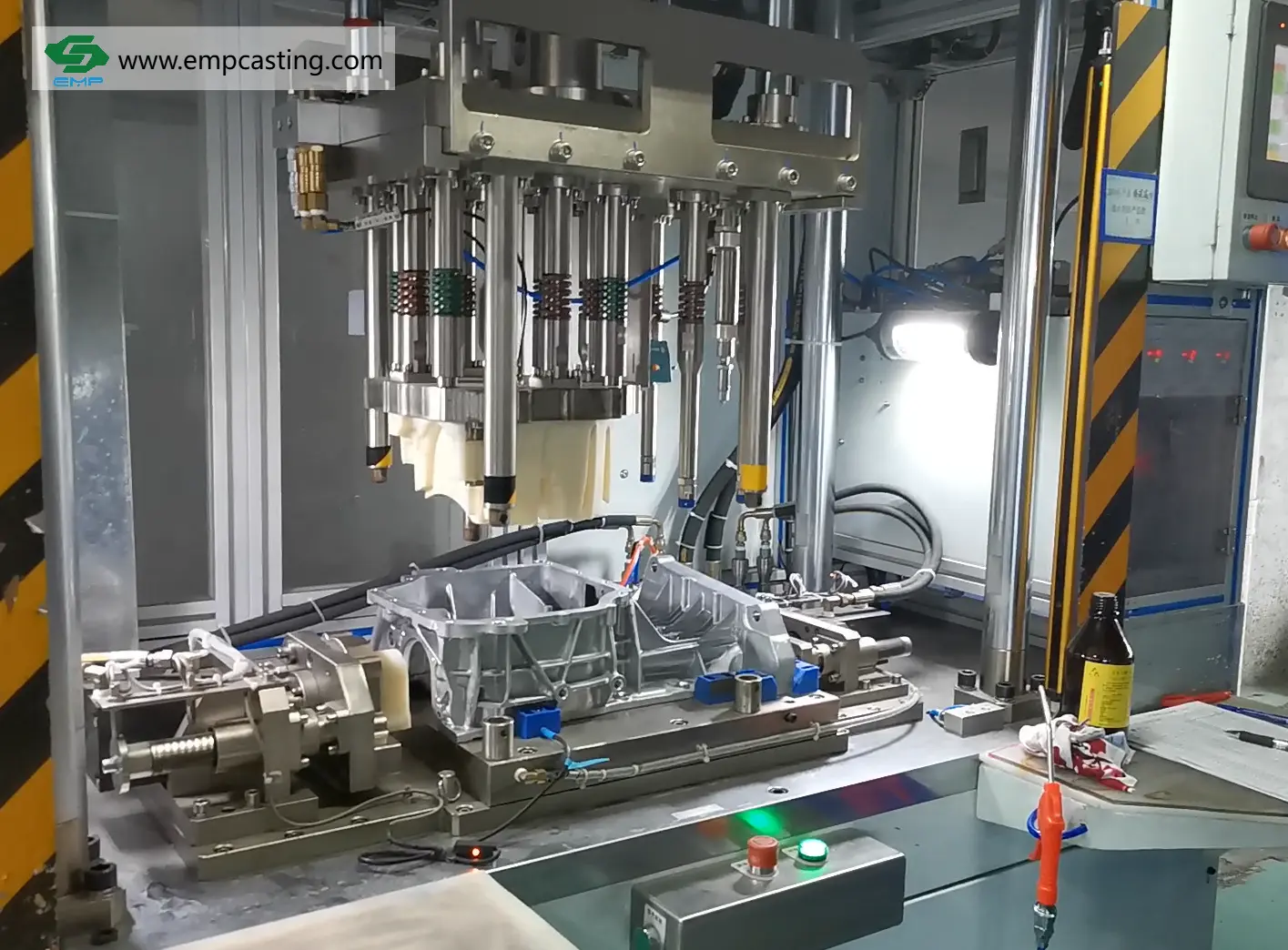

Electric Vehicle (EV) Systems

Battery Enclosures: High-pressure die-cast 3003/6061 aluminum shells protect lithium-ion cells while reducing weight by 40% vs. steel.

Motor Housings: Vacuum-assisted casting minimizes porosity (<0.1%), ensuring durability under 200°C operating conditions.

Performance & Racing Components

Hydraulic Handbrakes: Anodized aluminum drift handbrakes (e.g., AUSO-RACING models) withstand 500Nm forces, with M10 ports for rapid installation in BMW and Toyota platforms.

Suspension Parts: Forged aluminum control arms improve cornering stability, cutting unsprung mass by 25%.

Aesthetic & Functional Upgrades

Custom Wheels: 6061-T6 alloy rims with CNC-milled spokes reduce rotational inertia, boosting acceleration and fuel efficiency.

Body Kits: Hydroformed aluminum fenders and hoods achieve seamless curves (0.8mm thickness) for supercar aesthetics.

AI-Optimized Prototyping Machine learning algorithms analyze 10,000+ design iterations in 2 hours, identifying optimal wall thickness (1.5–3mm) and rib patterns to prevent deformation under load.

Hybrid Die Casting Tesla-inspired Giga Press technology produces single-piece rear subframes, eliminating 70+ welds and cutting production costs by 30%.

Surface Engineering

Micro-arc Oxidation (MAO): Creates 20μm ceramic coatings for brake calipers, withstanding 1,000+ salt spray hours.

Laser Etching: Adds anti-slip textures to pedal systems without compromising fatigue strength.

EV Boom: Global aluminum auto parts market projected to hit $910B by 2030, driven by EV adoption (40% CAGR).

Localized Production: 80% of Tier 1 suppliers now require regional CNC hubs (e.g., Guangdong/YMP facilities) to meet JIT delivery mandates.

Smart Factories: IoT-enabled presses auto-adjust parameters (pressure: 300–450 bar; temp: 680±5°C) for zero-defect batches.

Certifications: IATF 16949 and ISO 9001 compliance for automotive-grade quality.

R&D Capabilities: 15+ years’ experience in alloy development (e.g., hypereutectic Si alloys for high-wear applications).

Scalability: MOQs as low as 100pcs for prototypes, with DDP shipping to 160+ countries.