The automotive industry is in a state of constant evolution, driven by ever-tightening regulations on fuel efficiency and emissions, as well as unrelenting consumer demand for greater performance and reliability. At EMP, we believe in harnessing the latest manufacturing technologies to meet these challenges head-on. One such technology that stands out is die casting. In this blog, we'll explore why die casting is essential for modern automotive parts die casting and how it continues to shape the future of our industry.

Before diving into its importance, it's crucial to understand what die casting is. At its core, die casting is a manufacturing process that involves forcing molten metal into a mold cavity under high pressure. This technique allows for the mass production of metal parts with exceptional precision and minimal post-processing. Die casting alloys are often composed of aluminum, magnesium, zinc, and other metals known for their lightweight yet robust properties.

Precision and Complexity

One of the standout features of die casting in automotive industry is its ability to produce highly intricate components with incredible precision. Automotive parts often require complex geometries and tight tolerances to ensure proper functionality and fit. With die casting, manufacturers can achieve this level of precision consistently, reducing the need for secondary machining processes.

Lightweight and Durable Components

Die casting allows for the use of lightweight metals like aluminum and magnesium, which are essential for reducing the overall weight of vehicles. Lighter vehicles are more fuel-efficient and have lower emissions, which is a critical factor in meeting stringent environmental regulations. Despite being lightweight, die-cast components are known for their strength and durability, making them ideal for various automotive applications, from engine blocks to transmission cases.

High Production Rates

One of the primary reasons die casting is so prevalent in the automotive industry is its capacity for high-volume production. The process is designed for rapid molding cycles, enabling manufacturers to produce thousands of parts in a short period. This high production rate is essential for meeting the automotive industry's demand for large quantities of parts without compromising on quality.

Reduced Waste and Lower Costs

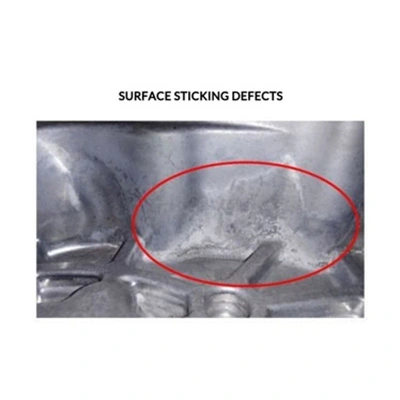

Die casting is not only efficient but also cost-effective. The process minimizes material waste, as excess metal can often be recycled and reused. Moreover, the high precision of die casting reduces the likelihood of defects, leading to lower scrap rates and fewer rejected parts. These advantages culminate in significant cost savings, which can be passed on to consumers or reinvested in further innovation.

Innovation in Electric Vehicles (EVs)

As the automotive landscape shifts towards electric vehicles (EVs), die casting remains a crucial manufacturing method. The lightweight and high-strength properties of die-cast components are vital for EVs, where battery efficiency and vehicle range are paramount. Additionally, die casting allows for the production of complex cooling systems and enclosures for batteries and electric motors, supporting the unique design requirements of EV technology.

Sustainability and Environmental Impact

Die casting also contributes to the automotive industry's sustainability goals. By enabling the use of recyclable materials and reducing energy consumption through efficient production processes, die casting aligns with the industry's push towards greener manufacturing practices. The ability to produce lightweight vehicles with reduced material usage further supports efforts to decrease the environmental footprint of car manufacturing.

At EMP, we recognize the indispensable role of die casting in automotive industry. Its unparalleled precision, cost-efficiency, and ability to produce lightweight and durable components make it an essential part of modern automotive manufacturing. As the industry continues to evolve, embracing new technologies and striving for sustainability, die casting will undoubtedly remain at the forefront, driving innovation and efficiency.

Whether it's the design of cutting-edge EVs or the production of high-performance internal combustion engine vehicles, the importance of die casting in automotive industry cannot be overstated. As we look to the future, EMP is committed to leveraging the full potential of die casting to meet the ever-changing demands of the automotive world.