In the automotive industry, high manufacturing standards are of paramount importance. Every component must be meticulously inspected and polished to ensure optimal performance and aesthetics. Among the many steps involved in automotive manufacturing, deburring aluminum plays a critical role. In this blog post, we will delve deeper into the significance of deburring aluminum and its impact on boosting automotive aluminum parts manufacturing standards.

Deburring aluminum parts is the process of removing burrs, which are small, unwanted projections of material that are often sharp and rough to the touch. These burrs can be present on various surfaces of the aluminum components used in automotive manufacturing. When left untreated, they can lead to numerous issues, including decreased efficiency, compromised safety, and damage to other components. Therefore, deburring aluminum is a crucial step to ensure the highest manufacturing standards.

Deburring aluminum enhances the efficiency of automotive manufacturing processes. Burrs can hinder the smooth operation of moving parts, such as gears or pistons. By eliminating these imperfections, the components can work seamlessly, optimizing the overall efficiency of the vehicle. Additionally, deburring aluminum improves the fitting of different parts, reducing the need for adjustments during assembly. This results in a streamlined production line, saving precious time and resources.

Safety is a top priority in the automotive industry. Deburring aluminum is essential to eliminate any sharp edges or rough surfaces that may pose a risk to the vehicle's occupants or mechanics during assembly. By eliminating burrs, rounded and polished surfaces are achieved, eliminating potential areas for injury. Consequently, deburring aluminum contributes to maintaining high safety standards in automotive manufacturing.

Visual appeal plays a significant role in consumer buying decisions. Deburring aluminum ensures a high-quality finish on automotive components, enhancing their overall aesthetic appeal. Burrs can give a rough and unfinished appearance to the aluminum surfaces, which is undesirable in the automotive industry. By removing these imperfections, deburring aluminum provides a polished and professional look, reflecting the commitment to craftsmanship and high standards of the automotive manufacturer.

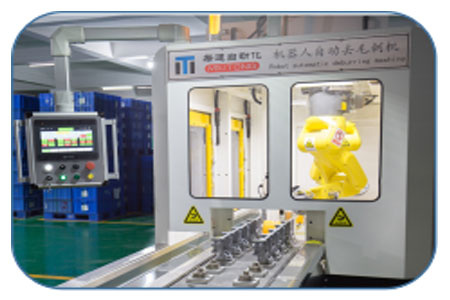

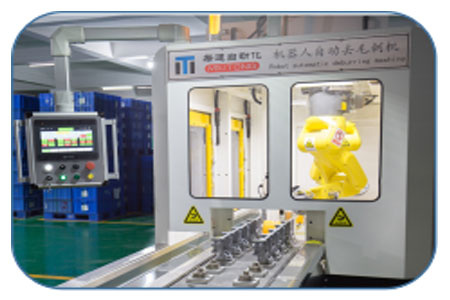

Deburring aluminum is a meticulous process that requires specialized equipment and expertise. Moreover, the automotive industry adheres to stringent regulations and quality standards that demand precise and consistent deburring techniques. Choosing the right deburring provider, like EMP, is crucial in ensuring the desired outcomes and meeting the highest automotive manufacturing standards.

At EMP, we understand the significance of deburring aluminum in the automotive industry. With our state-of-the-art deburring technology and skilled personnel, we are equipped to deliver superior deburring services. Our commitment to quality ensures that every aluminum component leaving our facility is free from burrs and meets the highest standards for efficiency, safety, and aesthetics.

In conclusion, deburring aluminum is a critical step in boosting automotive manufacturing standards. By removing burrs, deburring enhances efficiency, improves safety, and provides appealing aesthetics to automotive components. Choosing a reputable deburring provider, such as EMP-China aluminum alloy die casting factory, is vital in maintaining and exceeding the high-quality requirements of the automotive industry. Remember, when it comes to automotive manufacturing, every detail matters, and deburring aluminum plays a crucial role in achieving excellence.